I suppose that if you have arrived here by searching, you do not need to be told what a PCB board is.

But just in case, I will explain it to you briefly.

Do you remember when you were a child and you were curious to know what was inside there? (We are talking about electronic products, of course)

And one day you took it apart or it fell, and what was inside it?

Well, a green board, with many components and many solders.

Well, explained, the PCB board is the flat board where all the components of that electronic product are soldered and electrically interconnected.

Because the truth is that it is not very profitable in terms of time or money invested, unless you really like the subject and want to learn for fun.

Or maybe you have several prototypes in mind to be able to manufacture at home, and deciding on the final model is difficult, and you are like me, one of those who tries and fails.

The definitive solution to save time and money, especially if what you are working on is making several identical boards, is to order it from the kings of mambo (the Chinese).

There are countless foreign companies, especially Chinese websites, where you send the design, and they make it and send it to your home.

But the clear advantage of being able to make your own boards at home is that you can make them yourself. PCB, it's pretty obvious, you don't need to wait for it to be manufactured for you.

And especially if it's an untested design, you may not be able to afford to wait 40 days for the PCBs to arrive at your house, only to find out that you've made design errors, and need to make changes.

So it's clear that the biggest benefit of making your own PCBs at home is the immediate availability of them.

So if your situation is clearly one of "I cook it, I eat it", there are many things I can explain to you regarding this world of home PCB manufacturing.

There are countless ways to manufacture homemade PCB boards, from the always classic method of buying photosensitive PCB boards and causing the chemical reaction with ultraviolet light and photolithography, which will give as a final product a well-defined drawing on the copper plate.

But I am not going to do the typical historical of methods already known in history, but I am going to talk about the cool and modern methods, because that is why technology has advanced, to open the way for new methods, and not to be remembering the old ones.

Keep in mind that in most cases in our homemade PCB board manufacturing you need yes or yes a pre-cleaning the plate, on all the copper sides that we are going to use.

This cleaning refers to cleaning and degreasing, you know, using solvent or acetone (or isopropyl alcohol).

Since in most cases we are going to use chemical etching, if we do not do this cleaning very thoroughly, the etching could fail.

Can you make a homemade PCB with a vinyl cutter?

Yes.

Well, after all, it's like a mechanical printer, like a plotter, where you're going to attach a marker pen or blade.

There are several ways to make PCBs with a vinyl cutter.

Using the blade that comes with the vinyl cutter.

You simply paint the PCB with spray paint, to protect it from the corrosion of the ferric chloride.

And the blade simply scratches and uncovers the paint.

Scratching is not something that suits us, but it gives us a The cuts are not going to be very deep either.

The bad thing about this method is that the cuts are so fine that the perchloride will take a while to eliminate the exposed copper.

I don't see it as being at all recommendable, unless it's for playing or trying.

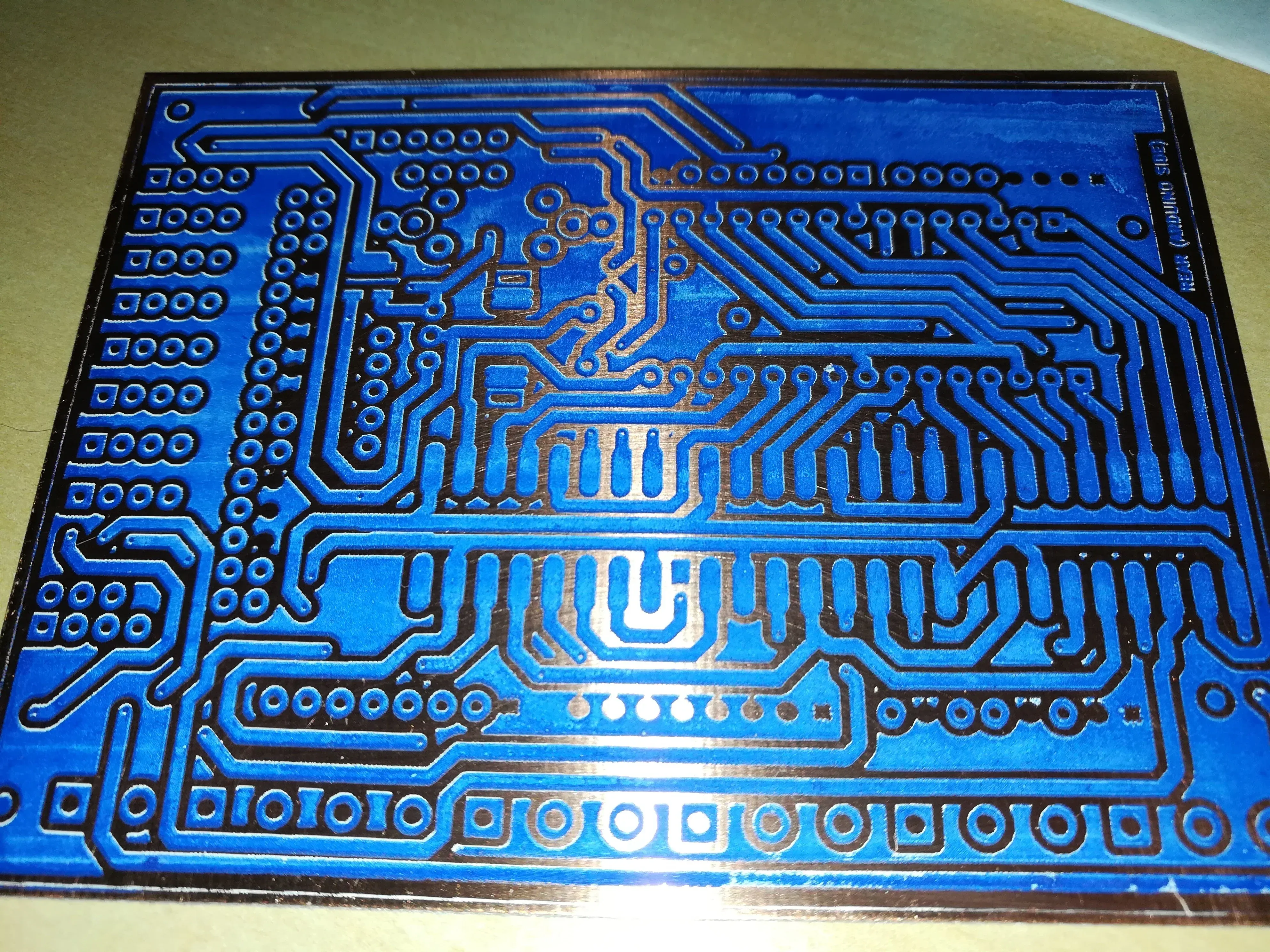

And it will end up like this.

Another method would be to stick a large sticker or vinyl on the board, so that it covers the entire PCB.

Then the blade will cut us this vinyl cover.

Once this process is finished we will have to manually remove strip by strip, those strips that will be the ones that we want to have the copper exposed.

It is entertaining, and it must be done very carefully because sometimes the vinyl moves or peels off.

Sometimes some sections are not even completely cut and when you pull on a section you take another one that you did not want to peel off.

This method is not very recommendable either, although it is very curious and fun.

We print the design of our PCB board on a normal sheet, the drawing always "mirrored", because this is going to be like a decal.

The sheet with the drawing printed with the toner of our printer is placed on a virgin PCB board already cleaned, and the plate is passed several times.

We let the board cool and immerse it in water, and we begin to rub the paper lightly with our fingers, and the paper will come off in shavings. We have to be careful, and the tricky thing is to get to the point where the paper that comes off is the one that should come off, and not the one that should stay. And there... sometimes we slip and have a cardio-respiratory arrest and have to start over.

There is no more to it, that's how the movie goes.

There is no specific technique nor is there technical data on how the times and temperatures should be for the home manufacture of PC boards using toner and an iron, although some users do give advice on this.

The quality of the paper and toner comes into play here.

So it is not an ideal practice nor advisable in the long term.

If it works for you today, bingo! It could stop working when you change the toner next time.

It is worth mentioning the high wear and tear on the printer, and the high toner consumption, especially if your designs include a background mask to preserve the copper.

The learning curve is quite high, and the wear and tear on the PCB board is also high, since the copper is damaged by each attempt and by each ironing.

The quality is quite acceptable, but it is always subject to the quality of the toner and the paper.

Normally we will have more or less hairs of the cellulose of the paper, so do not expect a detail of clues in the pure style of the old photo-development.

So Since this is not an exact science, depending on the day and your desire, some will turn out great and others will turn out awful awful awful.

Of course, when it turns out well, it looks like a plate taken from a sunbed.

I am not going to judge whether this method is advisable or not, it all depends on how you do it.

But I would say that if the subject is very difficult for you, move on to another story because your printer is probably not suitable for manufacturing your PCBs with this method with the laser printer toner.

This was a small revolution in the times when we used toner and iron to make our PCB boards at home.

I remember seeing it years ago on an American YouTube, I didn't find any more information than what he provided in the form of an experiment, and I decided to try it.

I improved it a bit with many tests and using bleach.

It worked so well, that this spread over the internet like wildfire.

The method is very very simple.

You can see it in datelle here:

We print the design as already explained in the printer and iron method.

And instead of using an iron, what we do is moisten it with a finger soaked in acetone, several times.

More or less we can guess that the toner has stuck to the board, by the tones of the paper itself.

With the paper on the PCB already dry, we put the board in hot water. (my special touch is to add bleach, it seems to help dissolve the paper quite well)

It depends on the quality and texture of the paper, we will have to break it up into shavings, or maybe it will come out whole in one piece.

The acetone cannot be pure as many people have been asking me in my youtube video.

Here in my country we call 'acetone' the product that women use to remove their nail polish.

Here we can balance the strength of the product, diluting it with water or not.

I use the "nail polish remover" product from Mercadona as such. (It's the one you can see in the photo of this title)

I also have it uploaded on YouTube:

This method is not only impressive, I would say that it is the most advanced in terms of precision and appearance.

But I warn you that this is getting into a very dark business.

It is very very complicated and has many obstacles.

I will tell you what it consists of.

You order a silkscreen screen (you can make it at home, but projecting the image on it is a real madness)

This screen is a frame, made of wood or aluminum, and inside the frame there is a synthetic fabric with a touch like latex.

This screen is a large weave of crossed threads, creating pixels. And there are screens of different resolutions.

On that screen the manufacturer has already projected an image on it, and that makes each of the holes in that screen covered or uncovered.

You can see it as the fabric of a stretched sweater.

What is the problem?

It is an expensive material that must be prepared by a specialized store.

The silkscreen screen will arrive with an image engraved on the screen, every time you pass paint through it you have to clean it immediately and very quickly.

Everything that dries on the screen will stay there forever, which is like saying that parts of the screen are dying. Imagine the fun.

It is a very very dirty method that will easily get you out of trouble.

You need a lot of space for maintenance and cleaning of the screen or screens.

Each design on your board needs a separate screen.

For example, if you want 2 double-sided boards, you will need 4 screens.

But if you also want to make the tracks on one side and the letters and drawings on the other, you will need 8 screens.

If you want the solder mask layer, multiply everything by 2 again.

I tried it, the result is impressive, but the effort is really extreme.

In English we will find it as "pcb milling"

and if you are interested I will explain it to you on this other page

Making homemade PCB using the CNC method (drill)

It is a very interesting method with many pros, and few cons.

It consists of painting the face of the plate with matte black paint, and with the laser we draw the lines that separate the tracks from the environment, exactly the same as we would do with the "pcb milling" method, but this is laser, gentlemen.

Advantages of the laser method

I am not going to talk about the benefits of this method because it is the method that I like, but I am going to use this method because it happens to be the method that I liked the most, for results, simplicity, and a curve of

And I point out the main advantages of designing a PCB with the laser pointer of our CNC.

- Extreme simplicity.

- Extremely silent. The only sounds will be the coolers and the axes, so you can work with it late at night.

- It does not produce environmental dirt or dirty our axes. Because the laser does not really decal or derail. It will only emit odors due to the evaporation of the material (normally paint)

- We do not care about the quality of the plate and its uniformity, or the leveling or stability of the bed, because the laser works and moves "flying"

- We do not need a height map, due to the previous point discussed in the "pcb milling" method

- There are no accidents. The laser will not collide with anything, because the laser works and moves "flying"

- We will never lose steps, because the laser does not rub against the material, nor is there anything that slows it down or hinders its passage.

- The work IS reversible.

If the laser produces something incorrect, or any situation causes us to lose homing, we can remove the paint and start over. (Because we are drawing a picture on the paint)

- The laser will not wear out or break, producing a different effect on the process (we were talking about the CNC blade, the tip does wear out)

- It is quite economical, the only expense is the use of paint, in very very low quantities.

Do you want to see how homemade PCB boards are made using the laser on the paint mask?

Visit this link -> Making homemade PCB using laser method on black paint mask